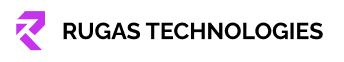

An advanced IoT solution for remote monitoring and predictive maintenance of Skanray's medical X-ray equipment, specifically their Surgical C-Arm systems.

SkanEye transforms equipment maintenance from reactive to proactive through comprehensive data collection, real-time monitoring, and machine learning-powered analytics. The system employs an IoT gateway using Node-RED framework to interface with the equipment's CAN bus, capturing critical communication data, detecting abnormal patterns, and identifying errors before they cause equipment failures. The platform performs sophisticated log file processing from console systems, analyzing events, errors, and patterns to predict component failures.

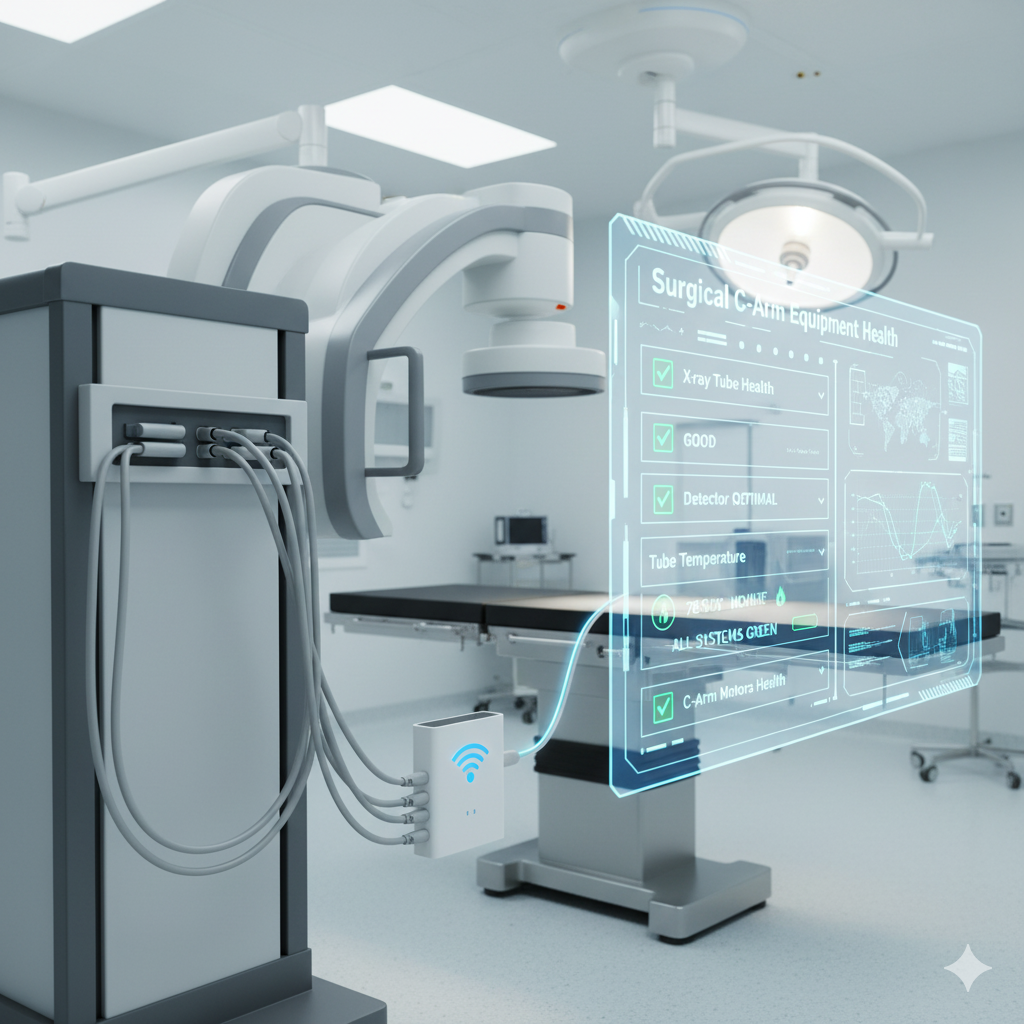

Additionally, the system monitors and reports poor quality DICOM images to R&D teams for analysis and continuous improvement. Built on a full-stack architecture using Node.js backend, Vue.js frontend, and MongoDB database, the cloud platform provides comprehensive dashboards for equipment status monitoring, alert management, analytics visualization, and equipment onboarding.

The solution enables Skanray to deliver superior customer support through predictive maintenance, reduce equipment downtime, and continuously improve product quality based on field data insights.